Long Term Fuel Trims Are Read by What Sensors

Home, Auto Repair Library, Automobile Parts, Accessories, Tools, Manuals & Books, Car BLOG, Links, Index

What Is Fuel Trim?

by Larry Carley copyright 2019 AA1Car.comFuel Trim is the adjustment the engine computer (PCM) makes to the fuel mixture to maintain a balanced air/fuel ratio. Fuel trim is usually displayed as a PERCENTAGE reading on a scan tool.

For lowest emissions, the engine computer tries to go on the fuel mixture balanced around 14.seven to 1 (xiv.seven parts of air to 1 part fuel). If the air/fuel ratio is less than xiv.7 to one (say 12 to i), the fuel mixture is RICH. A rich fuel mixture tin can produce more power (up to a point) only it also increases fuel consumption and emissions. Conversely, if the fuel mixture is greater than 14.7 to i (say 16 to one), it is LEAN. A lean fuel mixture reduces fuel consumption but can besides increase emissions if the air/fuel mixture is so lean that information technology fails to ignite and causes lean misfire.

The engine computer monitors the air/fuel ratio via the oxygen sensor(s) in the exhaust manifold(s). An oxygen sensor is essentially a RICH or LEAN indicator. When the engine is running lean (too much air and not enough fuel), the O2 sensor generates a depression voltage point that tells the engine calculator more fuel is needed. When the engine is running rich (too much fuel and non enough air), the O2 sensor produces a higher voltage signal that tells the engine figurer the engine is getting too much fuel and to cutting dorsum the fuel delivery. On vehicles that have an Wide Ratio Air/Fuel sensor (WRAF) or A/F sensor, the sensor tells the computer the exact air fuel sensor and so the estimator tin increase or subtract the fuel delivery as needed.

Authentic fuel trim values require an accurate feedback signal from the Oxygen sensor, otherwise the engine estimator has no manner of knowing whether the fuel mixture is running rich or lean.

When a common cold engine is showtime started, it may take 10 to 30 seconds or more than for the heaters inside the oxygen sensors to warms the sensors up to operating temperature. Until that signal is reached and the fuel feedback command arrangement goes into "airtight loop", the fuel mixture is stock-still at a predetermined value then no fuel trim adjustments are made. But once the Oxygen sensors are hot and the coolant temperature is high plenty for the computer to go into closed loop, the figurer starts to generate fuel trim values and brand adjustments in the fuel mixture.

When the engine is shut off, the fuel trim values are retained in the computer's retentiveness so the next time the vehicle is driven it tin pick upward where it left off. Erasing the estimator's memory with a scan tool or by disconnecting the battery or the PCM ability supply to clear codes also wipes the fuel trim values, which ways the computer has to outset learning the fuel adjustments all over once again the adjacent time the engine runs.

How to Read Fuel Trim

The fuel trim value is read by plugging a scan tool into the OBD Ii diagnostic connector located under the instrument panel (on the drivers side nigh the steering column). When the fundamental is turned on, the browse tool will initialize and starting time to communicate with the vehicle's onboard computer. Depending on the tool and the vehicle, information technology may be necessary to enter the vehicle year, make, model and engine VIN lawmaking before the scan tool can read the data.

The engine must be started and running to read the fuel trim data. Depending on the scan tool and how its menu options are set upwardly, you choose the option that allows you to read system live data. This will display a long list of sensor outputs and other readings called PIDs (Parameter IDs). On this list volition be two fuel trim values for inline 4 and half-dozen cylinder engines, and four fuel trim values for V6 and V8 engines (one pair for each cylinder banking company).

There are two types of fuel trim values shown:

Brusque Term Fuel Trim (STFT) is what the engine figurer is doing to the fuel mixture right now.

This value changes rapidly and tin bounce around quite a bit depending on engine load, speed, temperature and other operating atmospheric condition).

Values normally range from negative 10 percent to positive 10 percent, though the readings may jump as much as 25 percent or more in either direction.

Long Term Fuel Trim (LTFT) is a longer term average of what the engine computer has been doing to balance the fuel mixture over a predetermined interval of time.

This value is a more authentic indicator of how the fuel mixture is being corrected to recoup for changes in the air/fuel ratio that are occurring inside the engine.

STFT B1 is Brusk Term Fuel Trim engine cylinder Bank 1

STFT B2 is Curt Term Fuel Trim engine cylinder Bank 2

LTFT B1 is Long Term Fuel Trim engine cylinder Bank 1

LTFT B2 is Long Term Fuel Trim engine cylinder Bank 2

What Fuel Trim Values Hateful

POSITIVE fuel trim values hateful the engine computer is adding fuel (increasing the pulse width or on-time of the fuel injectors) to add more fuel to the engine. In other words, information technology is attempting to RICHEN the fuel mixture because it thinks the engine's air/fuel mixture is running too lean.

NEGATIVE (-) fuel trim values hateful the engine estimator is subtracting fuel (decreasing the pulse width or on-fourth dimension of the fuel injectors) to reduce the amount of fuel injected into the engine. This is done to LEAN out the fuel mixture to recoup for what it perceives equally a rich running condition.

Remember, all this is based on what the oxygen sensors are telling the engine computer. If the O2 sensors signal LEAN, the computer adds fuel and generates a POSITIVE fuel trim value. If the O2 sensors are reading RICH, the computer compensates by subtracting fuel and generates a NEGATIVE fuel trim value.

By reading the STFT and LTFT fuel trim values on a scan tool while your engine is running, you can tell if the air/fuel mixture is running rich (negative fuel trim percentages) or lean (positive fuel trim percentages).

What Fuel Trim Values Should Exist

Ideally, the STFT and LTFT should be inside a few per centum points of zero when the engine is idling or being held at a steady RPM. Recollect, STFT can bounce around quite a bit as when yous suddenly snap open the throttle or decelerate. But LTFT can tell y'all if the average fuel/mixture is running rich or lean.

Proficient LTFT values should be as close to zero every bit possible, though they can range from v to viii percent depending on the condition of the engine. If the LTFT is getting up effectually ten percentage or college, it usually indicates a problem that needs to be diagnosed.

LTFT values that go upward around 20 to 25 percentage volition unremarkably set a P0171 or P0174 lean code.

LTFT values that drop down to negative twenty to 25 will usually set a P0172 or P0175 rich lawmaking.

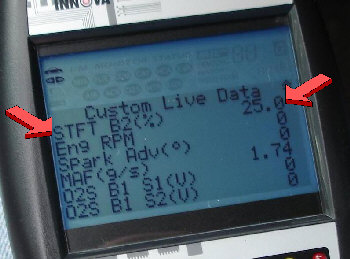

This scantool is displaying a STFT value of 25 pct. Unremarkably that would indicate a problem,

but in this case the engine is not running (Engine RPM is naught). As soon every bit the engine starts

and goes into airtight loop, the fuel trim readings volition begin to alter.

How Fuel, Ignition and Engine Problems Affect Fuel Trim

Lean fuel mixtures are a more common problem than rich fuel mixtures, though either can happen depending on the cause.

LEAN fuel mixtures will generate college than normal POSITIVE fuel trim readings on your browse tool.

RICH fuel mixtures volition generate NEGATIVE fuel trim values.

Possible causes of LEAN fuel mixtures include:

Air or vacuum leaks in the intake manifold, almost the throttle body or at vacuum hose connections.

Weak fuel pump that is not generating enough force per unit area or volume

Fuel line restrictions (similar a pinches hose or plugged filter)

A weak fuel force per unit area regulator that is not maintaining adequate fuel pressure

Air leaks in the PCV plumbing

Dirty MAF (Mass Airflow) sensor that is under reading airflow into the engine

Muddy or dead fuel injectors

Ignition misfire (a fouled spark plug, weak ignition curlicue or bad plug wire that causes a misfire allows unburned oxygen to pass into the exhaust and fool the O2 sensors)

Compression leaks (bad exhaust valve that allows unburned oxygen into exhaust and fools O2 sensors)

Exhaust manifold cleft or gasket leak (allows unburned air into exhaust and fools O2 sensors)

Bad O2 sensor (bespeak shorted to basis so the sensor reads lean all the fourth dimension)

Possible causes of RICH fuel mixtures include:

Leaky fuel injector

Excessive fuel force per unit area due to bad fuel pressure level regulator or restricted fuel return line

Extremely muddied air filter or restrictions in air intake system

Exhaust restrictions (clogged converter, crushed exhaust piping or plugged muffler)

Bad O2 sensor (output shorted to voltage and then information technology reads RICH all the time)

Using Fuel Trim to Diagnose Problems

Use Fuel Trim to Diagnose Vacuum and Fuel Delivery Leaks. With the engine idling, await at the Short Term Fuel Trim (STFT) and Long Term Fuel Trim (LTFT) values. Normal range may be loftier as plus or minus 8, but closer to zip is best. If the numbers are +ten or higher for STFT and LTFT, your engine is running LEAN. Rev the engine to 1500 to 2000 RPM and concur it steady for one-half a minute or then. If the fuel trim numbers drops back down to a more normal reading, information technology confirms the engine has a vacuum leak at idle. This is because vacuum leaks accept less of a leaning event on the fuel mixture equally engine speed and load increase.

If the fuel trim readings practise not change much, the lean fuel condition is more than likely due to a fuel commitment problem (weak fuel pump, restricted fuel filter, dirty fuel injectors or a leaky fuel pressure level regulator) than a vacuum leak.

LTFT fuel trim readings that are trending high might also be the consequence of a slight ignition misfire that is not bad enough yet to prepare a misfire lawmaking simply is bad enough to cause a drop in fuel economy. I or more fouled spark plugs that are misfiring occasionally, or a weak ignition coil or bad plug wire that is allowing some occasional misfires could be the cause. For more than information on misfire diagnose, Click Here.

You can use fuel trim to identify dirty fuel injectors. If the LTFT fuel trim readings are trending up (POSITIVE), it ways the fuel feedback command system is compensating for an air/fuel mixture that is condign progressively leaner over time. The most likely cause would exist dingy fuel injectors. Fuel delivery tin can exist restricted by the accumulation of varnish deposits inside the injector nozzles. The fix here is to clean the injectors. If the fuel trim values return to normal afterward the injectors have been cleaned, it verifies you have solved the trouble. If the fuel trim values don't change after cleaning the injectors, the lean fuel condition may be due to low fuel pressure or air/vacuum leaks.

You can use fuel trim readings to bank check the response of the oxygen sensors and engine computer to changes you make in the fuel mixture. While the engine is idling, temporarily disconnect a vacuum hose. You should see the STFT fuel trim readings leap immediately and become POSITIVE, and the LTFT should start to pitter-patter upwards in response to the bogus lean fuel mixture you have merely created by disconnecting the vacuum hose.

To examination a rich response, you can feed some propane vapor from a modest propane tank into the throttle body or a vacuum hose connection on the intake manifold. This fourth dimension, you should run across a drop in fuel trim readings, with STFT going NEGATIVE, and LTFT creeping downward in response to the rich fuel mixture.

No modify in fuel trim readings when you lot create an artificial lean or rich fuel mixture would tell you the engine computer is NOT operating in closes loop, or that the oxygen sensor(south) are not responding to changes in the fuel mixture.

Click Here to Download or Impress This Article.

More than Fuel System Articles:

More than Fuel System Articles:

Air/Fuel RatiosFuel Trim by Wells Manufacturing (PDF file).

Ford P0171 & P0174 Lean Codes

How Fuel Injection Affects Emissions

Most Common Trouble Codes (and what causes them)

Mass Airflow Sensors

Oxygen Sensors

Wide Ratio Air Fuel (WRAF) Sensors

More than on Check Engine Lights & Error Code Diagnostics

Browse Tool Diagnostics

Decoding Onboard Diagnostics

TROUBLE CODES Help

OBD II Diagnostic Tips

Help with DTC P0300 Random Misfire Codes

Troubleshoot Fuel Injectors

Troubleshoot Electronic Fuel Injection & Fuel Pump Diagnosis

Be sure to visit our other websites:

Auto Repair Yourself

CarleySoftware

OBD2HELP.com

Random-Misfire.com

Browse Tool Assistance

Problem-CODES.com

Source: https://aa1car.com/library/what_is_fuel_trim.htm

More than Fuel System Articles:

More than Fuel System Articles:

Post a Comment for "Long Term Fuel Trims Are Read by What Sensors"